Études de cas

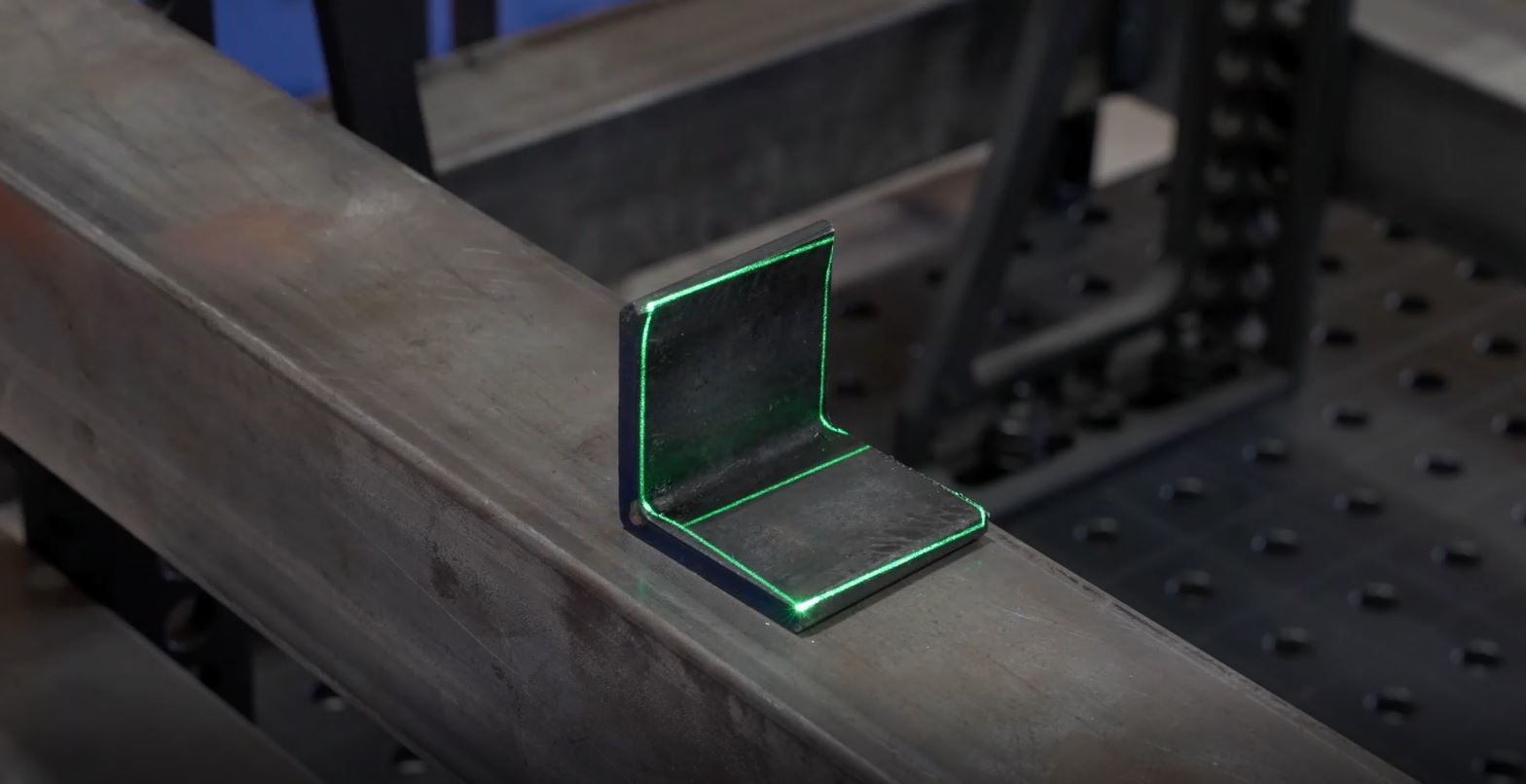

En mettant en œuvre le système LTG de Virtek, Metalcrafters of Wayne County, Inc. a transformé ses processus de fabrication, en gagnant du temps, en améliorant la précision et en s'attaquant aux goulots d'étranglement causés par les méthodes de mise en page traditionnelles. Au-delà de la fabrication, la valeur du système LTG en tant qu'outil de contrôle de qualité garantit que chaque pièce répond aux normes exactes, renforçant ainsi la réputation de Metalcrafters sur

pour la fourniture de travaux métalliques de haute qualité.

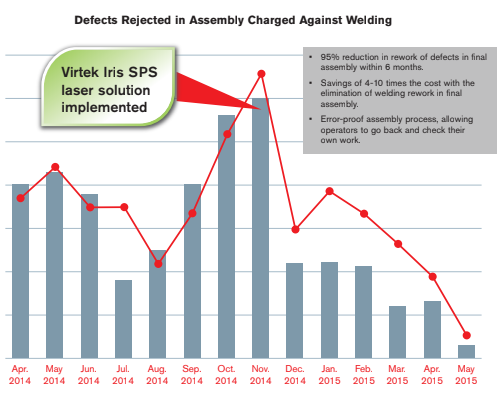

Komatsu a pu éliminer l'utilisation de gabarits, les mesures manuelles, les étapes de marquage et d'ajustement et a pu mettre le processus d'assemblage à l'abri des erreurs.

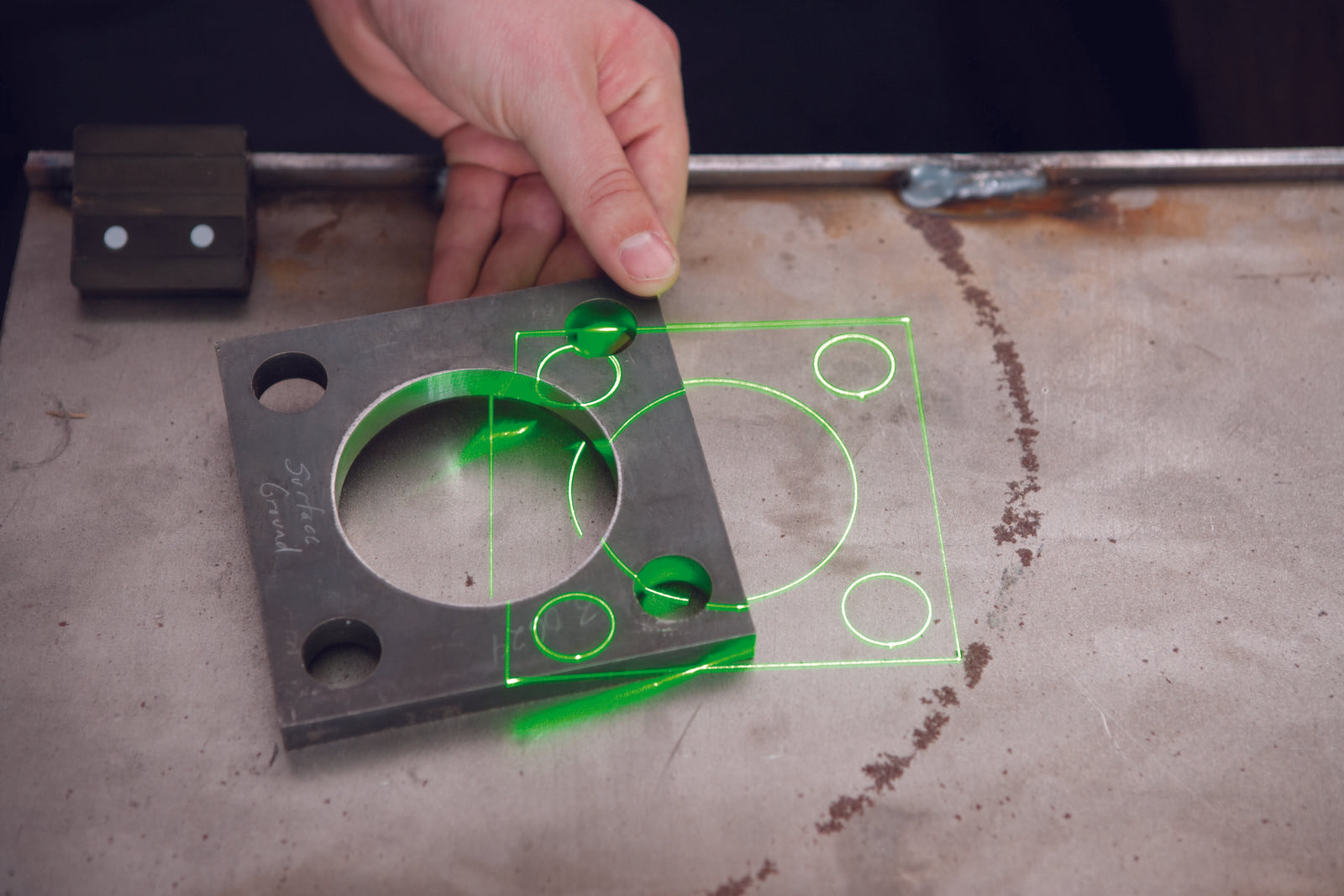

Dans le secteur de la fabrication, chaque étape du processus de production est une occasion de gagner du temps et de l'argent. En projetant avec précision un faisceau de lumière laser sur des surfaces, la technologie de projection laser guide efficacement les opérations de fabrication, ce qui permet de réaliser des économies dans des applications telles que l'assemblage, le modelage et l'inspection.

Weldall a réduit les temps de préparation de 6 ou 7 heures à 1,5 heure sur certaines pièces et atteint une précision de 100 %.

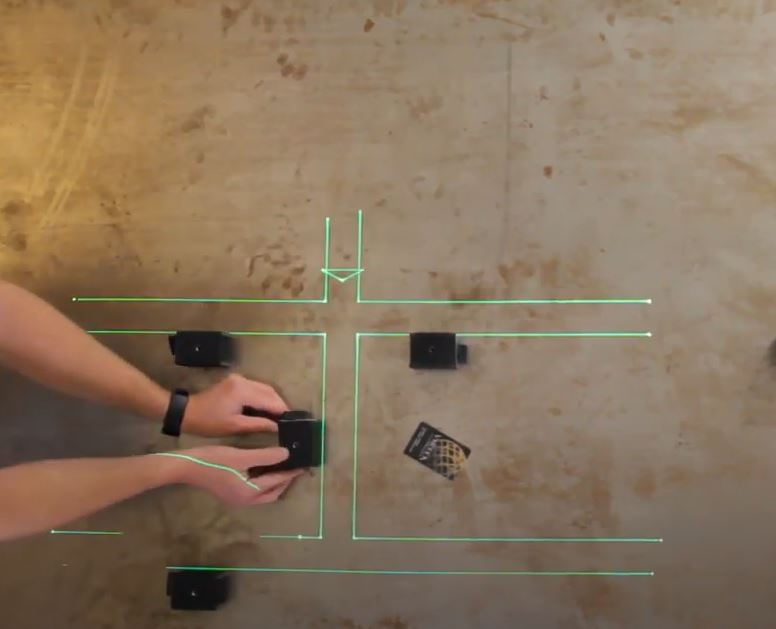

Le système de main courante de XOVR utilise la projection laser de Virtek et permet d'assembler des panneaux muraux jusqu'à 5 fois plus vite !