Le nouveau logiciel de suivi en temps réel de Virtek révolutionne les tâches d'assemblage sur des pièces mobiles

Élimination de la fabrication de modèles et de la fixation pour accélérer considérablement la mise sur le marché.

WATERLOO, Ontario, Canada (1er juin 2021) - Virtek annonce la sortie de son logiciel de positionnement laser Iris™ ActiveTrack qui projette en continu des lignes laser stables et précises sur des pièces en mouvement pour guider les ouvriers dans une variété de processus de fabrication. Même les formes complexes en 3D sont projetées avec précision, ce qui accélère considérablement les délais de mise sur le marché et garantit la qualité des produits.

" Iris ActiveTrack permet aux techniciens de positionner la bonne pièce, au bon endroit, au bon moment, même lorsque la pièce est en mouvement ", déclare Sean Francoz, chef de produit du groupe Virtek. "C'est une technologie qui change la donne et qui aidera nos clients à réduire leurs coûts en éliminant le temps passé à examiner des documents, à mesurer, à marquer et à utiliser des gabarits pendant les processus d'assemblage. Les gains les plus importants proviennent de l'élimination des reprises causées par les échappées de qualité."

Parallèlement au lancement d'Iris ActiveTrack, Virtek a également publié la dernière édition de son logiciel Iris 3D avec une API (Application Programming Interface) améliorée. Cette amélioration comprend une base de données de rapports de production. Accessible via l'API, l'outil de rapport de production fournit un accès à distance instantané à l'état actuel de la production pour n'importe quel système sur le site. Il permet également de récupérer des données de production détaillées à n'importe quel moment de l'historique du système. Les responsables de la production peuvent ainsi analyser les performances au niveau macro (processus complet) ou micro (cellule de travail ou tâche individuelle).

L'API améliorée d'Iris 3D comprend un ensemble d'outils puissants qui permettent aux utilisateurs d'employer le système de positionnement par vision (VPS) de Virtek pour localiser un outil ou un composant ciblé n'importe où dans le champ de vision du système et signaler la position de l'outil par rapport au projecteur. Cette fonctionnalité informe les opérateurs de l'état du système, de sa position dans le flux de travail global, et fournit des données numériques sur les tâches effectuées.

La société norvégienne Kongsberg Defence & Aerospace (KDA), client de longue date de Virtek, utilise les systèmes de projection laser de Virtek dans ses installations de production depuis début 2000. "Notre site de production à Kongsberg, en Norvège, dispose de plusieurs systèmes de projection laser qui soutiennent des programmes complexes avec des clients internationaux majeurs", a déclaré Lars Kveseth, directeur technologique de KDA, Aerostructures. "Les solutions de Virtek nous ont permis de dépasser nos objectifs de coût et de qualité."

"D'autres mises à niveau et innovations du système, comme IRIS 3D et le nouveau logiciel Iris ActiveTrack, donnent des résultats passionnants", a ajouté M. Kveseth. "Dans certaines applications, nous constatons une réduction des coûts de 30 % et une amélioration de la qualité de 25 %."

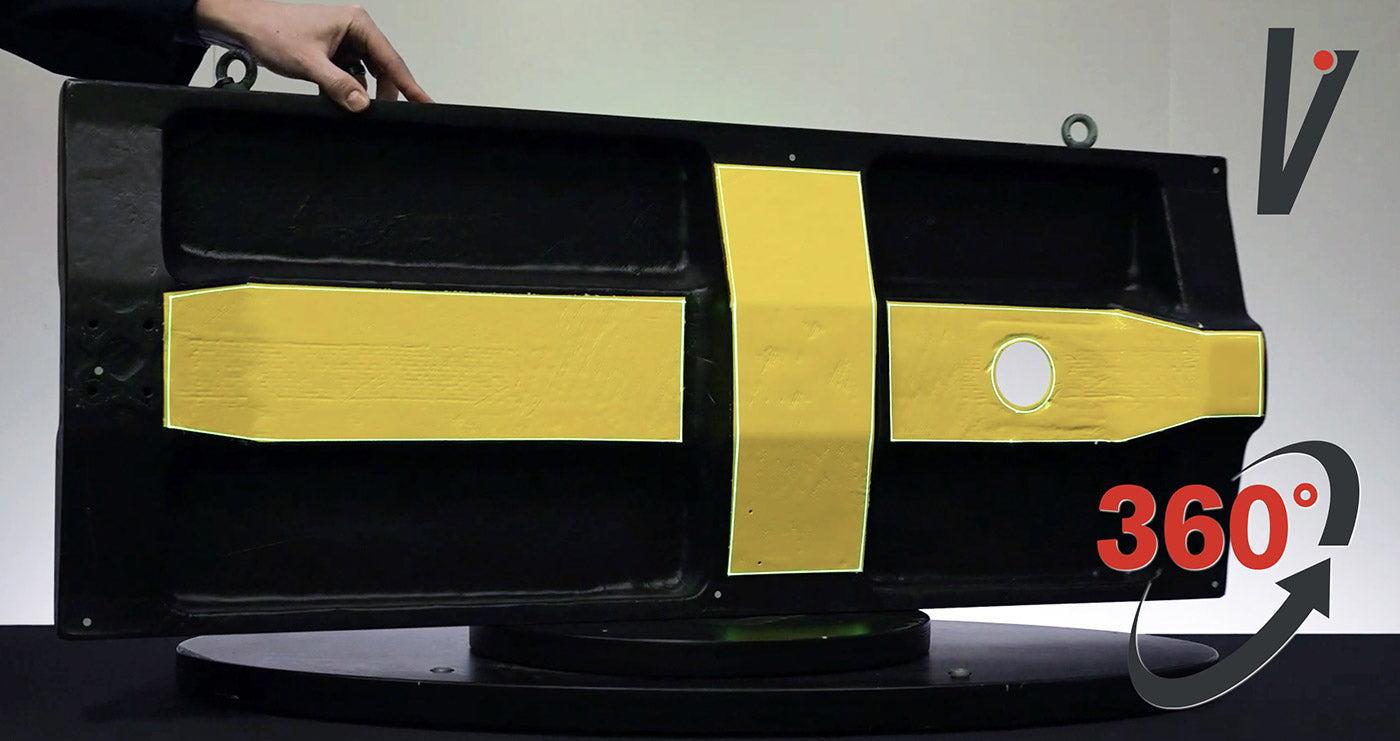

"Par exemple, nous utilisons actuellement la technologie ActiveTrack d'Iris pour le masquage assisté par laser dans notre département de préparation des surfaces et nous constatons d'importantes améliorations du débit qui devraient réduire les coûts de 20 %."

"Nous explorons également l'utilisation de cette technologie dans nos opérations d'assemblage et dans les domaines où le système de projection laser pourrait remplacer les montages de localisation coûteux afin de réduire davantage les coûts et les délais dans l'atelier. Dans l'ensemble, KDA est très satisfait du soutien et de la coopération que nous avons reçus de Virtek au cours des deux dernières décennies."

Pour plus de détails, et pour discuter des besoins de votre organisation, contactez votre représentant commercial Virtek.