Nouvelles

Nouvelles

Le contrôle et la gestion des stocks sont essentiels à la réussite de toute entreprise, car ils constituent la base d'opérations efficaces et d'une rentabilité globale. Pour les fabricants en particulier, les stocks représentent un investissement substantiel, mobilisant des ressources et un espace de stockage précieux - sans parler du personnel nécessaire pour gérer les entrées et les sorties. Le maintien de niveaux de stocks optimaux est crucial, car il permet aux fabricants d'honorer leurs engagements envers leurs clients et de remplir efficacement leurs fonctions essentielles.

Le contrôle des stocks est au cœur de l'approche centrée sur le client de Virtek Vision et constitue la clé du maintien d'un avantage concurrentiel et d'un résultat net solide. Fondée en 1986 à Waterloo (Ontario), l'entreprise produit plus de 1 000 projecteurs laser de précision par an, avec l'aide d'une centaine d'employés dans le monde entier. Environ 50 % des activités de Virtek Vision consistent à fournir des pièces et des équipements de projection laser à l'industrie aérospatiale, mais l'entreprise travaille également avec les secteurs verticaux de la construction, de la fabrication industrielle, de la construction modulaire, de l'énergie renouvelable et de l'automobile.

Selon Dietmar Wennemer, PDG de Virtek Vision, la recherche et le développement constituent un autre moyen de répondre aux besoins complexes de ses nombreux clients de premier plan, notamment les principaux fabricants OEM de l'aérospatiale, la Formule 1 et les grands fabricants industriels. "Un pourcentage important de notre chiffre d'affaires est réinvesti dans la technologie qui aide nos clients à fabriquer leurs produits", explique M. Wennemer, soulignant l'importance de l'amélioration de la productivité et de la satisfaction des clients. La nature complexe des produits de Virtek Vision exige que le personnel de l'entreprise soit rompu à l'ingénierie avancée, avec des connaissances qui se répercutent sur l'expérience positive de l'utilisateur.

En quête de croissance

Dans un souci constant d'amélioration de l'efficacité, M. Wennemer explique que l'entreprise a reconnu la nécessité d'un système holistique de gestion des stocks. Confrontée à un système de planification des ressources de l'entreprise (ERP) obsolète et à la nécessité d'améliorer la gestion et le contrôle des coûts, Virtek Vision a cherché un nouveau système de gestion des stocks. "Nous avions de nombreuses étapes de comptage des stocks qui nous coûtaient une journée d'immobilisation par mois", ajoute-t-il.

Lors de sa recherche d'un nouvel ERP, l'entreprise a donné la priorité à une solution de gestion complète, incluant la fabrication de matériel et les outils de contrôle des stocks et des ordres de travail. Les outils de planification, d'ordonnancement, d'octroi de licences et de gestion de la chaîne d'approvisionnement présentaient également un intérêt, explique M. Wennemer. "Le processus a été principalement piloté par les finances et les opérations, ainsi que par les ventes, car nous voulions disposer d'un configurateur et d'un système de vente adéquats", ajoute-t-il, notant l'objectif de suivre tous les articles entrant et sortant de l'entrepôt par le biais d'un ERP et d'éviter de compter manuellement les articles. "Il était important que notre travail de fabrication soit irréprochable et que nous ayons un contrôle des coûts adéquat... et un suivi en temps réel."

Les évaluations ont commencé au printemps 2022, et après avoir choisi l'ERP Kinetic d'Epicor basé sur le cloud, Virtek Vision a travaillé avec Six S Partners pour mettre en œuvre et déployer Kinetic avec succès. Située à proximité du siège de Virtek Vision, Six S est un partenaire précieux pour Virtek Vision.

"Leurs consultants et leur équipe pouvaient se rendre sur place pour aider à former notre équipe, en particulier en ce qui concerne les opérations", explique M. Wennemer à propos des changements apportés au processus. "Lorsque des problèmes se posaient, l'équipe était disponible pour nous aider et les résoudre.

Grâce à une expérience utilisateur intuitive et configurable, complétée par des outils d'apprentissage intégrés à la plateforme, Kinetic permet à l'équipe de Virtek Vision de bénéficier d'une visibilité en temps réel de l'inventaire et de surveiller les effets d'entraînement qui accompagnent les changements.

"Si de légères modifications sont apportées à une commande, nous savons quel en est l'impact sur la main-d'œuvre", explique M. Wennemer, en soulignant que des coûts cachés peuvent souvent se glisser dans le processus. "Désormais, lorsqu'un bon de travail est clôturé, nous savons immédiatement combien d'heures ont été consommées par le produit.

En outre, comme le fait remarquer M. Wennemer, la possibilité de relier différents secteurs de l'entreprise, des finances et de l'administration aux équipes de vente et de service, y compris l'intégration de la plateforme avec Salesforce, réduit les erreurs manuelles et permet une plus grande efficacité.

"Je suis un grand fan de l'automatisation", explique-t-il. "S'il n'y a jamais d'entrée manuelle dans le système, il y a moins d'erreurs, et c'est ce qui a guidé l'équipe.

Des ajustements pour l'avenir

Wennemer explique que l'équipe continue d'apprendre le système et que de nouvelles améliorations sont mises en œuvre chaque jour. Les tableaux de bord personnalisables permettent aux membres appropriés des différents départements de créer la valeur et les rapports nécessaires. À l'avenir, les processus seront ajustés et l'équipe de Virtek Vision analysera les données fournies par Kinetic, avant de les utiliser pour prendre des décisions dans l'atelier de fabrication.

La société investit également dans un système de levage vertical qui, selon M. Wennemer, sera étroitement intégré à Kinetic afin d'améliorer encore les données d'inventaire et de réduire les heures de comptage, ce qui permettra aux principaux décideurs de Virtek Vision d'avoir une meilleure visibilité des coûts globaux et de la rentabilité.

"La rationalisation de la gestion des stocks est très importante", explique M. Wennemer, qui souligne le coût élevé de certaines pièces et de certains composants utilisés par Virtek Vision. "S'il est contrôlé par un système auquel vous pouvez faire confiance, c'est là que réside l'avantage.

Pour en savoir plus sur Virtek Vision, veuillez consulter le site www.virtekvision.com.

Source : par Canadian Manufacturing Online

https://www.canadianmanufacturing.com/features/empowering-efficiency-through-inventory-management/

#1 Transformation numérique

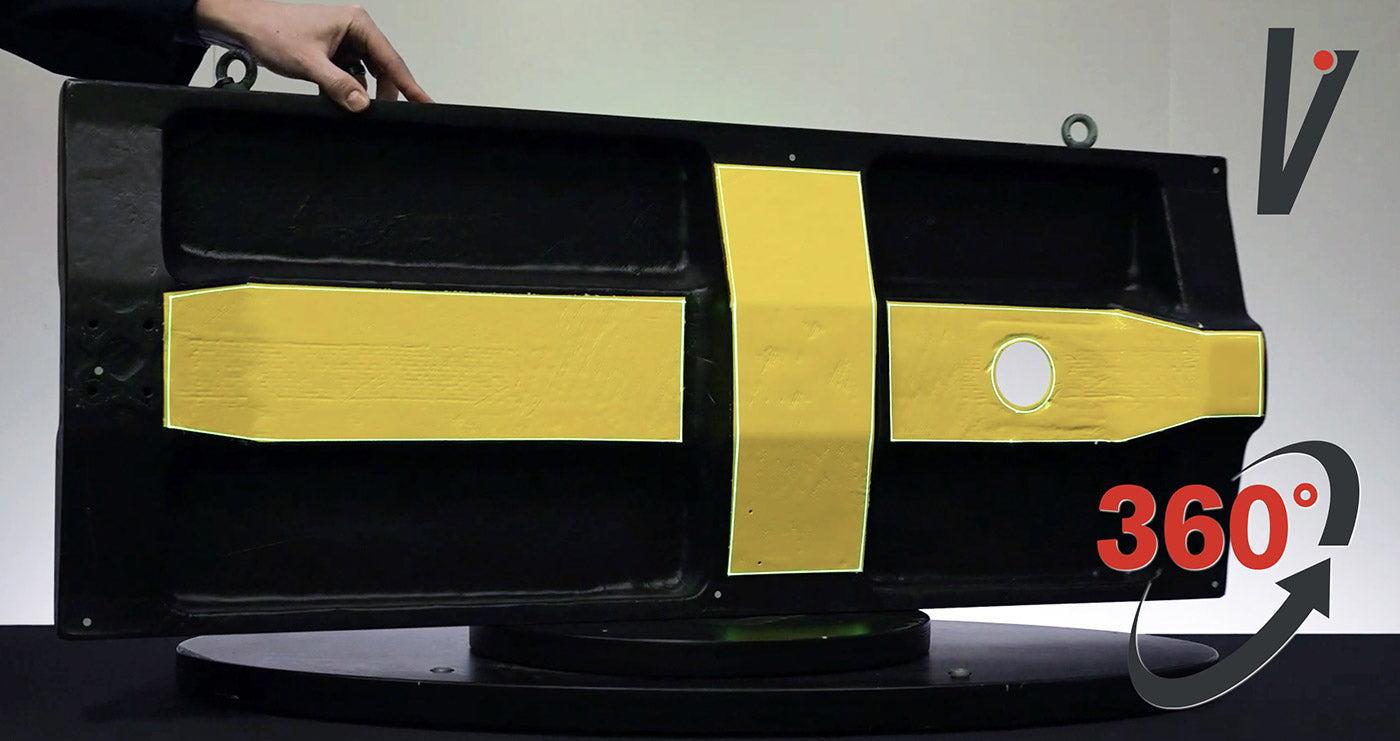

Les modèles laser virtuels et les données numériques de Virtek permettent d'améliorer l'efficacité du flux de travail et la productivité, en donnant aux opérateurs les moyens d'agir au sein même de l'atelier.

#2 Compatibilité avec l'industrie 4.0

Virtek embrasse l'industrie 4.0 avec des solutions avancées connectant les machines, les processus et les personnes. Grâce à l'automatisation, à l'échange de données, au modelage laser virtuel et aux logiciels, les fabricants parviennent à créer des usines intelligentes et connectées, améliorant ainsi la productivité et la compétitivité.

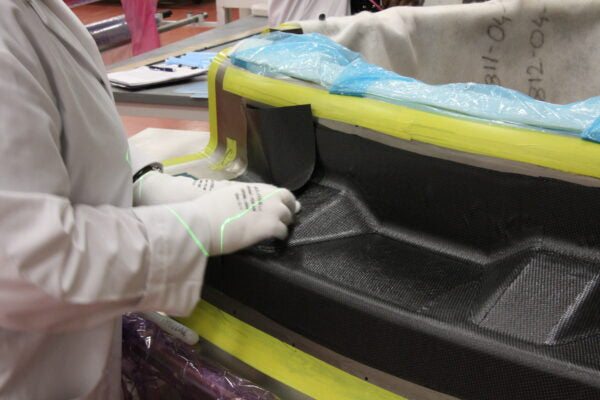

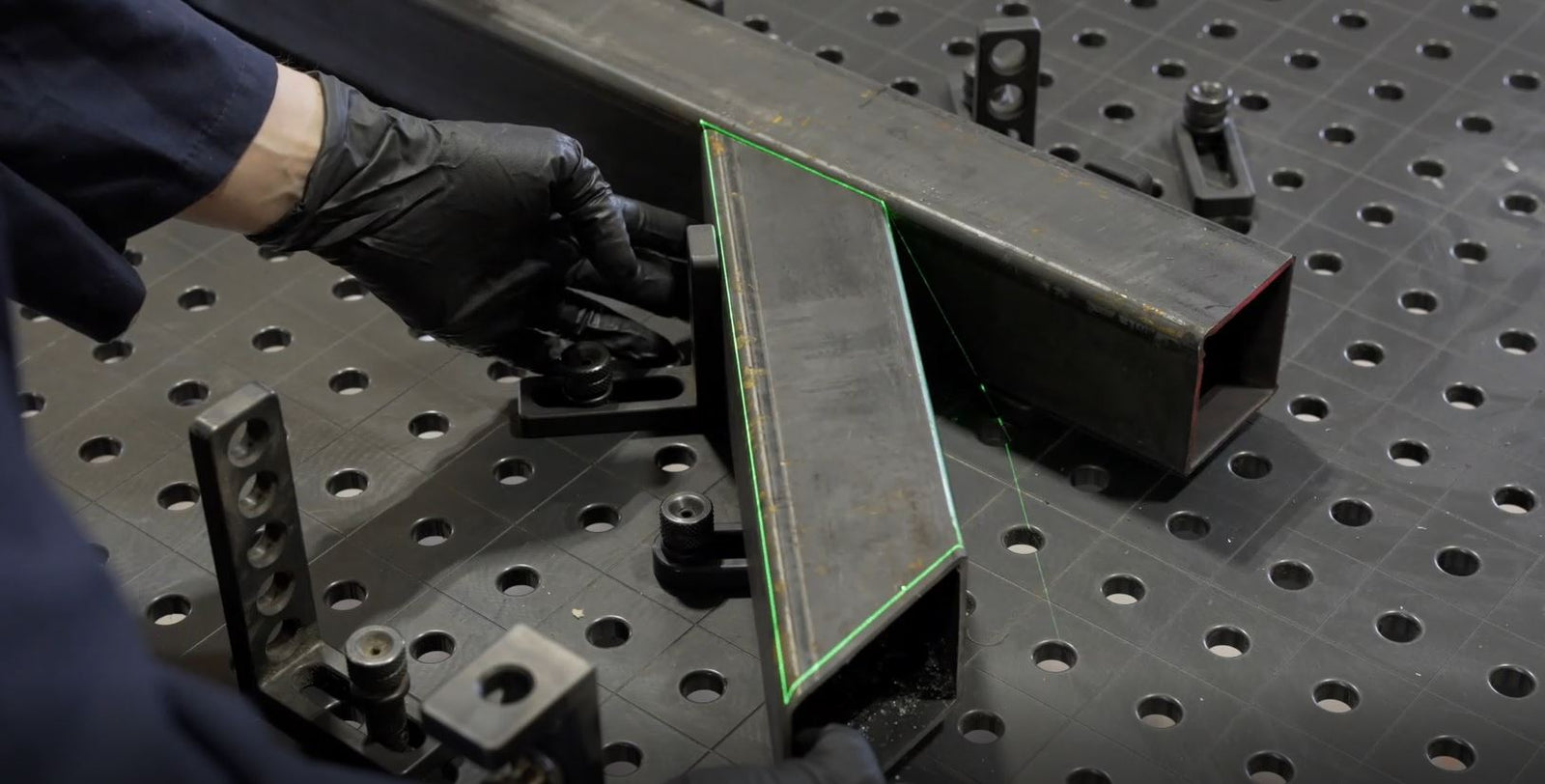

#3 Laser-Guided Assistance

Les solutions d'assemblage à guidage laser de Virtek révolutionnent la fabrication. Les projections laser de haute précision permettent une exécution précise et efficace des tâches, réduisant ainsi le déficit de compétences. Les gabarits laser numériques guident les opérateurs, éliminant les mesures et les erreurs manuelles, améliorant la qualité et accélérant la production.

#4 Processus rationalisés

Notre offre unique permet aux opérateurs de travailler directement sur la pièce, ce qui améliore l'efficacité et permet une prise de décision rapide dans l'atelier.