Nouvelles

Nouvelles

- L'efficacité libérée : Réduire les temps de cycle dans la fabrication de composants

- Minimiser les retards : Stratégies de réduction des risques pour les constructeurs

- Construire plus vite ou mieux, un compromis ?

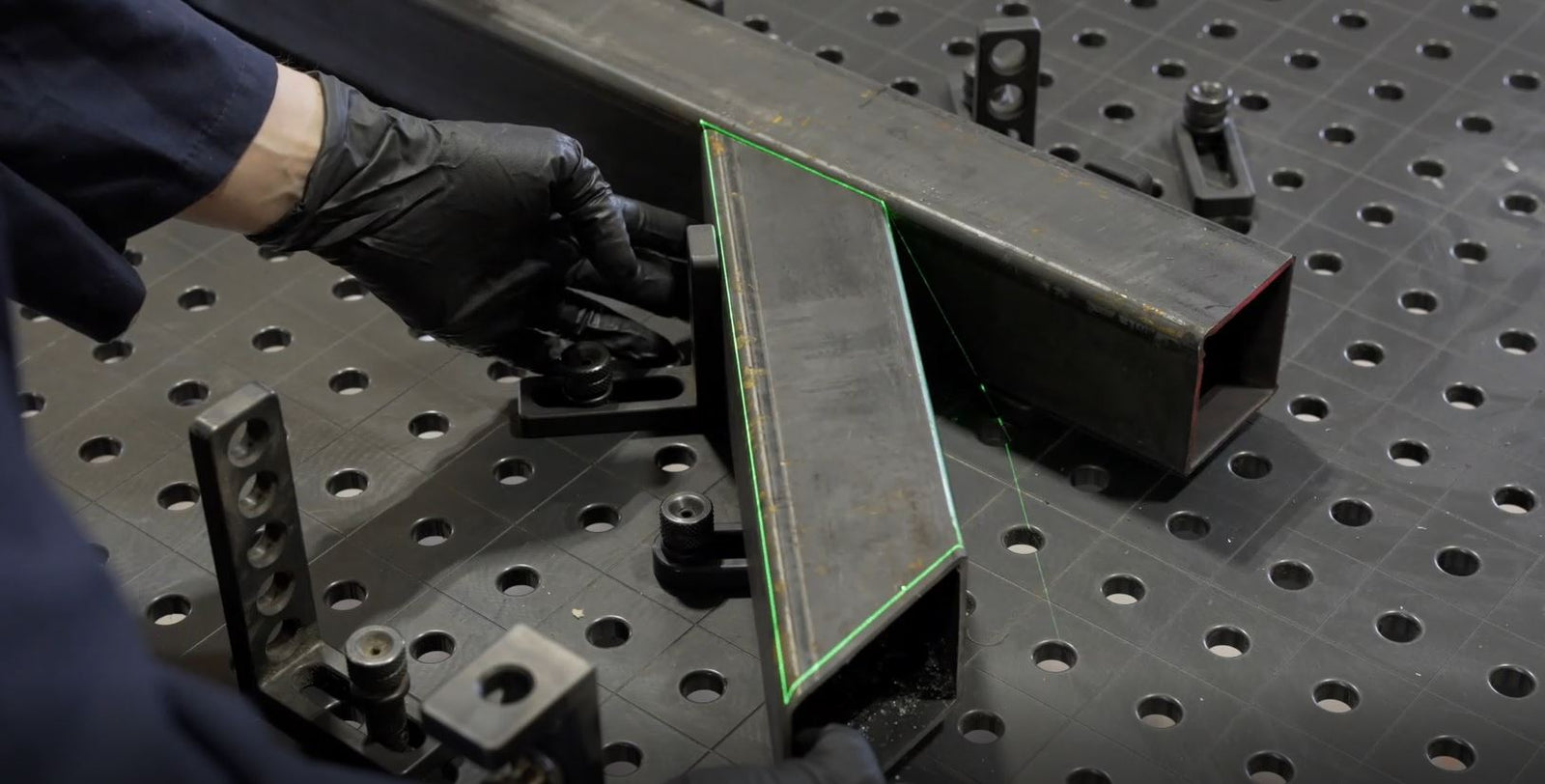

- Précision laser : Transformer la fabrication des composants

- Ensemble nous construisons : Confiance et collaboration dans la construction

#1 Transformation numérique

Les modèles laser virtuels et les données numériques de Virtek permettent d'améliorer l'efficacité du flux de travail et la productivité, en donnant aux opérateurs les moyens d'agir au sein même de l'atelier.

#2 Compatibilité avec l'industrie 4.0

Virtek embrasse l'industrie 4.0 avec des solutions avancées connectant les machines, les processus et les personnes. Grâce à l'automatisation, à l'échange de données, au modelage laser virtuel et aux logiciels, les fabricants parviennent à créer des usines intelligentes et connectées, améliorant ainsi la productivité et la compétitivité.

#3 Laser-Guided Assistance

Les solutions d'assemblage à guidage laser de Virtek révolutionnent la fabrication. Les projections laser de haute précision permettent une exécution précise et efficace des tâches, réduisant ainsi le déficit de compétences. Les gabarits laser numériques guident les opérateurs, éliminant les mesures et les erreurs manuelles, améliorant la qualité et accélérant la production.

#4 Processus rationalisés

Notre offre unique permet aux opérateurs de travailler directement sur la pièce, ce qui améliore l'efficacité et permet une prise de décision rapide dans l'atelier.

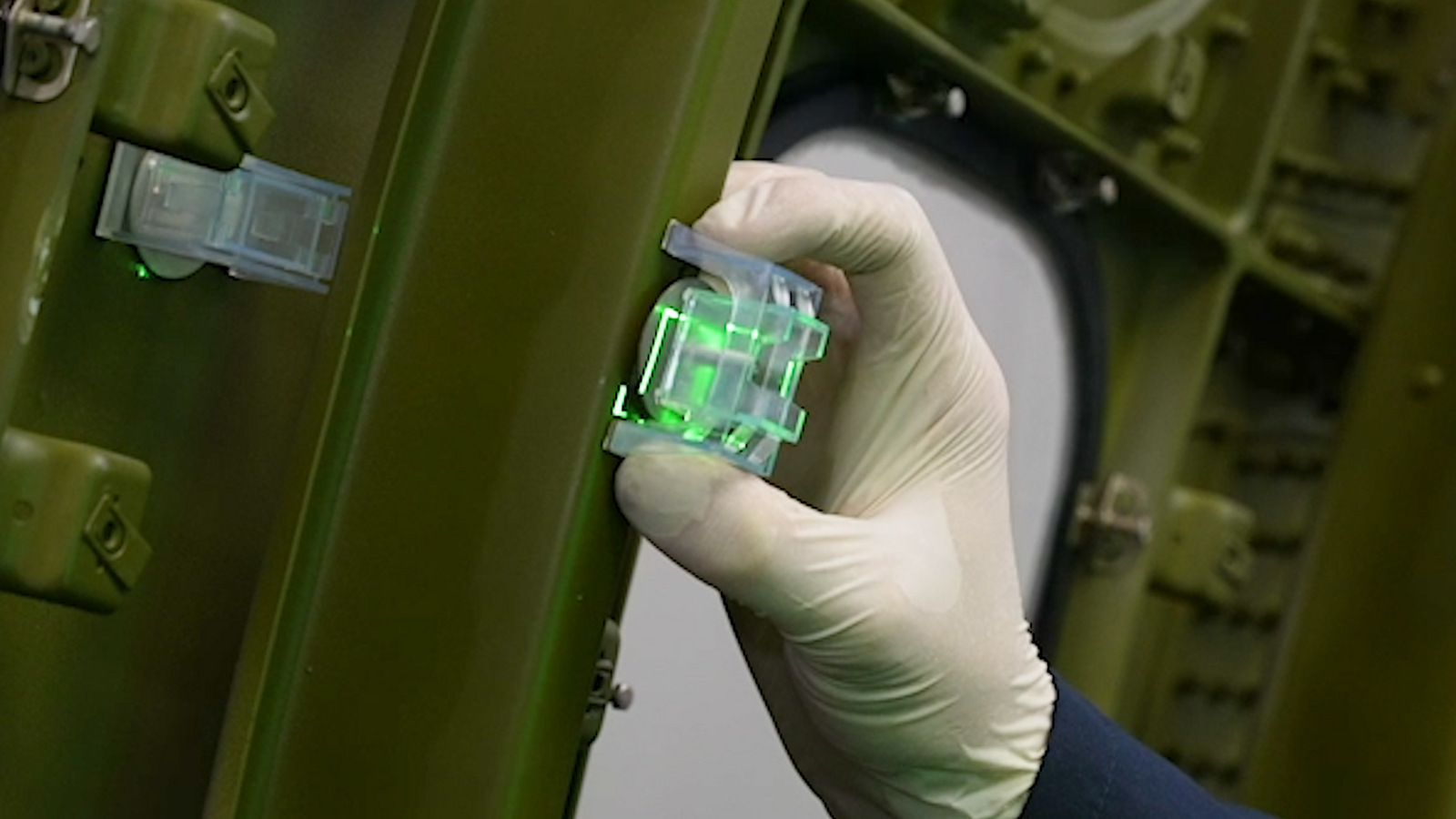

Dans une session de questions-réponses, Dietmar Wennemer, PDG de Virtek Vision, révèle comment les solutions de projection laser de l'entreprise contribuent à améliorer rapidement la production de pièces aérospatiales.

Les processus tels que la découpe, le placement et la mise en place sur l'outillage de moulage peuvent ajouter un temps considérable à la production de pièces en composite de carbone dans les applications aérospatiales, en particulier lorsqu'il s'agit de grandes structures comme les ailes.

La plateforme logicielle Iris de Virtek, associée au système de positionnement par vision (VPS), permet aux opérateurs de construire des pièces composites sans utiliser de gabarits physiques encombrants qui doivent être soulevés et retirés manuellement du moule pendant que le matériau est fixé en place. Le système projette un contour laser de la pièce ou du matériau pour guider facilement l'opérateur.